Effective Vacuum Pump Care Strategies for Reliable Performance

- Ben Tomblin

- Jan 9

- 4 min read

Vacuum pumps are the unsung heroes in many industrial settings. They keep processes running smoothly, from manufacturing to food processing. But like any machine, they need proper care to perform at their best. I’ve learned that effective vacuum pump maintenance is not just about fixing problems when they arise. It’s about preventing them with smart, regular care. Let me share some practical tips that help keep vacuum pumps in top shape, reduce downtime, and save costs.

Why Vacuum Pump Care Strategies Matter

Vacuum pumps work hard. They create the pressure difference needed for various industrial tasks. Without them, many processes would stall. But pumps face wear and tear from constant use, exposure to contaminants, and temperature changes. Neglecting maintenance can lead to:

Reduced efficiency

Unexpected breakdowns

Higher energy consumption

Costly repairs or replacements

Implementing solid vacuum pump care strategies means spotting issues early and extending the pump’s lifespan. It also ensures your operations stay reliable and productive. I always recommend a proactive approach rather than waiting for a failure.

Key Vacuum Pump Care Strategies to Follow

Here are the core strategies I use and recommend for maintaining vacuum pumps effectively:

1. Regular Inspection and Cleaning

Dirt, dust, and debris can clog your pump and damage internal parts. Inspect your pump regularly for signs of contamination or wear. Clean filters, strainers, and intake areas to keep airflow smooth. For example, in food processing, airborne particles can quickly build up, so cleaning schedules must be strict.

2. Monitor Oil Levels and Quality

Many vacuum pumps rely on oil for lubrication and sealing. Check oil levels frequently and top up as needed. But don’t just add oil blindly. Use the right type recommended by your pump manufacturer or your lubricant supplier. Thames Lubricants Ltd offers custom, high-performance lubricant solutions tailored to your pump’s needs. Also, change the oil at intervals suggested in the manual or sooner if it looks dirty or smells burnt.

3. Check for Leaks and Seal Integrity

Leaks reduce vacuum efficiency and can introduce contaminants. Inspect seals, gaskets, and connections for cracks or wear. Replace any damaged parts immediately. A tight seal keeps your pump running smoothly and prevents costly energy loss.

4. Monitor Operating Temperatures

Vacuum pumps generate heat during operation. Excessive heat can damage components and degrade oil. Use temperature sensors or infrared thermometers to keep an eye on operating temperatures. If you notice overheating, investigate causes like blocked cooling fins or insufficient lubrication.

5. Listen for Unusual Noises

A sudden change in sound can signal mechanical issues. Bearings, vanes, or motors may be wearing out. Regularly listen to your pump during operation. If you hear grinding, knocking, or whining, schedule maintenance before a breakdown occurs.

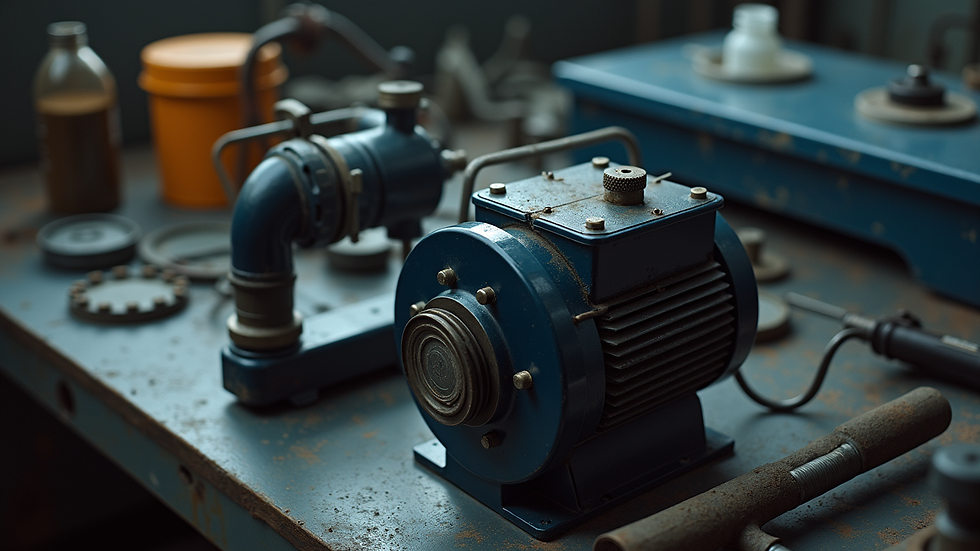

Close-up view of vacuum pump motor and oil reservoir

Lubrication: The Heart of Vacuum Pump Maintenance

Lubrication is critical. It reduces friction, prevents wear, and helps seal the vacuum chamber. But not all oils are created equal. Using the wrong lubricant can cause damage or reduce pump efficiency. Here’s what I focus on:

Choose the right lubricant: Consult your pump’s manual or a trusted supplier like Thames Lubricants Ltd for custom blends that match your pump’s operating conditions.

Maintain oil cleanliness: Contaminated oil accelerates wear. Use filters and change oil regularly.

Avoid overfilling: Too much oil can cause foaming and reduce vacuum quality.

Use synthetic oils if possible: They often last longer and perform better under extreme conditions.

Proper lubrication extends pump life and keeps your processes running without hiccups.

Troubleshooting Common Vacuum Pump Issues

Even with good care, problems can arise. Here are some common issues and how to tackle them:

Pump won’t start: Check power supply, fuses, and motor condition.

Low vacuum pressure: Inspect for leaks, dirty filters, or worn seals.

Excessive noise or vibration: Look for loose parts, worn bearings, or misalignment.

Overheating: Ensure proper ventilation, check oil levels, and clean cooling fins.

Oil contamination: Change oil and investigate source of contamination, such as process gases or moisture.

Regular monitoring and quick action prevent minor issues from becoming major headaches.

High angle view of vacuum pump maintenance tools and oil containers on workbench

Scheduling Maintenance for Maximum Uptime

A maintenance schedule is your best friend. It keeps tasks on track and ensures nothing is overlooked. Here’s a simple plan I recommend:

Daily: Check oil level, listen for unusual sounds, and inspect for leaks.

Weekly: Clean filters and intake areas, check belt tension if applicable.

Monthly: Inspect seals, gaskets, and electrical connections.

Quarterly: Change oil, clean cooling fins, and perform a detailed inspection.

Annually: Full service by a qualified technician, including parts replacement if needed.

Adjust this schedule based on your pump’s workload and environment. Keeping a maintenance log helps track performance and spot trends.

Partnering with Experts for Custom Solutions

Sometimes, off-the-shelf lubricants and maintenance plans don’t cut it. That’s where partnering with specialists makes a difference. Thames Lubricants Ltd focuses on flexible blending and packing to deliver custom, high-performance lubricant solutions. Their expertise helps reduce downtime and improve reliability tailored to your specific vacuum pump and industrial needs.

If you want to learn more about their services, check out their website here.

Keep Your Vacuum Pumps Running Smoothly

Vacuum pump care strategies are essential for keeping your operations efficient and trouble-free. Regular inspection, proper lubrication, leak checks, and scheduled maintenance all play a part. Don’t wait for a breakdown to act. Stay proactive, use the right lubricants, and partner with experts when needed.

By following these tips, you’ll extend your pump’s life, reduce energy costs, and avoid unexpected downtime. That’s a win for your business and your bottom line.

Comments